Janet Gbur, PhD

|

Research Interests Aerosol Jet Printing, Fatigue and Fracture of Biomedical Materials, Medical Device Reliability and Subcomponent Mechanical Characterization, Microscale Reliability Testing, Material Characterization, Failure Analysis |

Dr. Janet Gbur earned her Ph.D. in Materials Science and Engineering from Case Western Reserve University, a Masters of Engineering in Mechanical Engineering and Bachelors of Engineering in Materials Engineering from Youngstown State University, and Bachelors of Science in Biology/Pre-medicine from Kent State University. She is a Research Biomedical Engineer for the VA and Research Assistant Professor in the Department of Materials Science and Engineering at CWRU.

At CWRU, Dr. Gbur is a staff member in the APTC-affiliated Advanced Manufacturing and Mechanical Reliability Center (AMMRC) and the Nitinol Commercialization Accelerator Laboratory (NCAL), which provide tools to better understand materials processing and mechanical reliability as well as develop a better understanding of Nitinol, a nickel-titanium alloy used in cardiovascular applications and orthodontia.

Dr. Gbur can be reached by email at jlg120@case.edu.

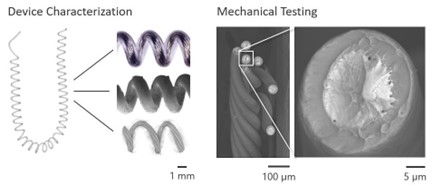

Figures: Connecting material and device structure to performance. Selection of characterization techniques is essential for device evaluation, whether it is digital optical microscopy, scanning electron microscopy, or more advanced imaging such as X-ray microscopy. Coupled with mechanical and reliability testing, these enhance the understanding of device performance and are also key tools in device development and failure analysis.

The purpose of Dr. Gbur's research is to examine how material structure informs mechanical properties ultimately affecting performance, in particular, of devices used in medical applications. Her research goals include developing miniaturized medical devices using aerosol printing technology and advancing the field of fatigue and fracture of medical materials and devices in three specific areas:

- Using advanced characterization techniques to understand structure at relevant size and length scales with correlation to long term performance

- Developing techniques to better understand the movement and translation of devices in vivo in order to better inform reliability testing and standards development

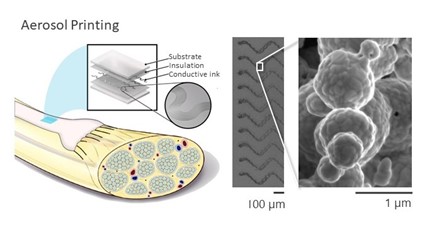

- Using aerosol printing to create flexible circuits for biomedical applications including implantable components for neural prosthesis systems

Figures: Device design and characterization of aerosol-printing parameters. Optimization of ink deposition and the ink-substrate interface requires a suite of characterization techniques to determine the effects of changes in printer focus ratio, stage heating, print speed, atomizer voltage, and sintering time/temperature. Digital optical microscopy, scanning electron microscopy, and optical profilometry are key characterization tools for evaluation of the printed trace dimensions and print quality. Once printing parameters are optimized, additional evaluation follows with electrical testing, adhesion testing, and mechanical reliability testing.

Dr. Gbur is also dedicated to mentoring STEM undergraduates and provides opportunities for students to learn the art of research, practice science communication, and develop project management skills. Students participate in active, lab-bench focused research projects and work with collaborators to add meaningful contributions to research benefitting medical device development, testing, and translation.

Figures: Students actively participate in national and local conferences to share their work and practice communicating their science. Group members represent a variety of engineering disciplines and work collaboratively to solve engineering questions related to materials, mechanics, and medical device development.

Published work:

- Fatigue and fracture of wires and cables for biomedical applications

- Plasma Focused Ion Beam Serial Sectioning as a Technique to Characterize Nonmetallic Inclusions in Superelastic Nitinol Fine Wires

- Determining Morphology and Size Distribution of Nano-scale Features in Conductive Ink for use in Aerosol Jet Printing